Aviation heat exchangers are essential for managing temperature across numerous onboard systems in modern aircraft. From cooling jet engines to stabilizing cabin conditions and avionics, these devices ensure the reliability, performance, and safety of aircraft under extreme operational environments. As aviation transitions toward electric propulsion, autonomous systems, and ultra-light aircraft, advanced heat exchanger technologies are at the forefront of innovation, blending thermodynamics with cutting-edge materials, smart systems, and compact design.

Hidden Roles of Heat Exchangers in Aviation

In the aviation sector, heat exchangers serve several critical but often overlooked roles:

Avionics Cooling

- Modern aircraft avionics produce considerable heat due to complex flight control systems, radar, and onboard computers.

- Specialized liquid-cooled or air-cooled heat exchangers are used to maintain optimal temperature, preventing electronic failure.

Fuel System Conditioning

- At cruising altitudes (30,000–40,000 feet), external temperatures can drop below -50°C.

- Aviation heat exchangers pre-warm jet fuel to prevent fuel waxing, ensuring flow integrity and preventing blockage in lines or filters.

Environmental Control Systems (ECS)

- Cabin air is regulated using air cycle machines and heat exchangers to manage temperature and pressure.

- Heat exchangers help exchange heat between bleed air from engines and ram air to condition cabin air.

Hydraulic Oil Cooling

- Aircraft systems like landing gear, flaps, brakes, and control surfaces rely on high-pressure hydraulics.

- Oil coolers ensure that hydraulic fluid stays within optimal temperature, preserving viscosity and performance.

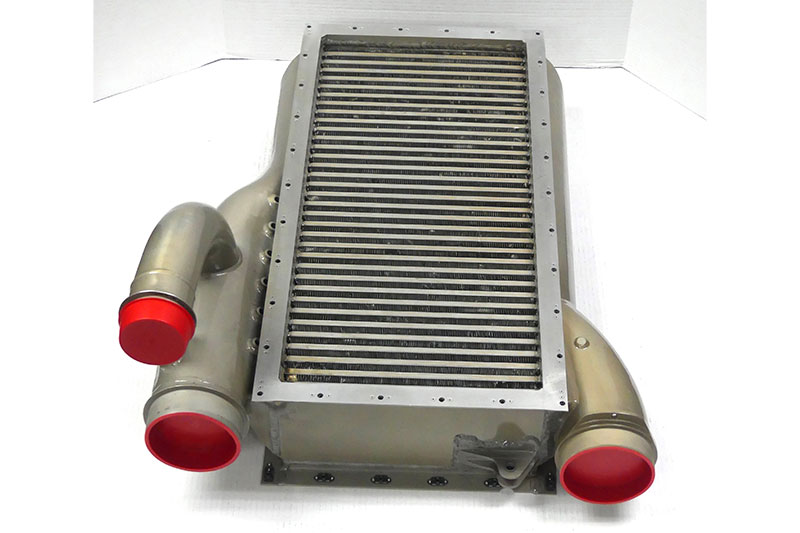

Types of Aviation Heat Exchangers

Air-to-Air Heat Exchanger

- Used in ECS and air cycle machines.

- Operates on bleed air and ram air interaction.

- Includes plate-fin and crossflow designs.

Fuel-to-Air or Fuel-to-Oil Heat Exchanger

- Leverages fuel as a cooling medium, absorbing waste heat from engine oil or electronics.

- Helps prevent fuel freezing at high altitudes.

Oil-to-Air Heat Exchanger

- Found in the lubrication systems of engines and auxiliary power units (APUs).

- Often integrated into engine nacelles or gearboxes.

Ram Air Heat Exchanger (RAHX)

- Uses outside air (ram air) captured during flight.

- Essential for military jets and UAVs where stealthy, passive cooling is needed.

Advanced Design Innovations

Multi-Functional Integration

- Newer systems integrate heat exchangers directly into load-bearing structures (like wing spars) to save weight and volume.

Self-Healing Materials

- Experimental exchangers use polymers or alloys that re-seal minor cracks, preventing in-flight leaks without maintenance downtime.

Phase-Change Coatings

- Coated with micro-encapsulated PCM (Phase Change Materials) to buffer short bursts of high heat loads (e.g., rapid descents or missile evasion).

3D Printed Heat Exchangers

- Allows complex flow paths, weight reduction up to 60%, and customizable cooling zones.

- Used in next-gen fighter jets and drones.

Smart and Adaptive Heat Exchanger Systems

Next-gen aviation platforms are moving toward digitally managed heat exchangers with adaptive features:

Sensor-Embedded Heat Exchangers

- Embedded temperature, pressure, and flow sensors offer real-time data on performance.

- Allows predictive maintenance—reducing aircraft downtime.

AI-Controlled Heat Management

- Some advanced aircraft link exchanger operation with autonomous flight control systems.

- AI dynamically adjusts airflow, bypasses, or fluid rates based on altitude, load, and weather conditions.

Variable Geometry Exchangers

- Include adjustable fins or louvers that respond to airflow rate and optimize thermal transfer at different flight speeds or altitudes.

Emerging Applications in Future Aviation Platforms

Aviation heat exchangers are also being customized for next-gen air mobility and space access:

Electric Aircraft and eVTOLs

- Battery and electric motor systems need efficient, lightweight cooling.

- Liquid-cooled plate heat exchangers using dielectric fluids are becoming common.

Urban Air Mobility (UAM)

- Space and weight are premium in eVTOLs. Engineers are using composite heat exchangers with high surface-area-to-volume ratios.

- Cooling is critical to both safety and performance during repeated vertical takeoffs and landings.

Hypersonic and Spaceplane Vehicles

- At speeds over Mach 5, skin temperatures exceed 1,000°C.

- Heat exchangers using fuel as coolant (regenerative cooling) are embedded under fuselage or nose cones to manage skin heating.

Key Challenges in Aviation Heat Exchanger Design

Designing a heat exchanger for aviation is vastly more complex than for ground systems:

Weight vs Performance

- Every gram of material affects fuel efficiency and payload. Engineers must find the perfect thermal efficiency-to-weight ratio.

Corrosion and Fatigue Resistance

- Constant exposure to hydraulic fluids, salt-laden air, and temperature cycling demands materials like Inconel, titanium, and aluminum-silicon alloys.

Maintainability and Inspection

- Must be easy to inspect for blockages, cracks, or thermal degradation.

Aviation Heat Exchanger is a cornerstone of aircraft thermal management—quietly protecting engines, electronics, and life-critical systems under extreme conditions. As the industry advances toward electrification, autonomy, and high-speed flight, these devices must evolve to be smarter, lighter, stronger, and more efficient. Through materials innovation, smart diagnostics, and compact designs, modern heat exchangers are not just components—they are intelligent enablers of the next era of aerospace engineering. Whether it’s a high-altitude drone, a supersonic fighter jet, or an urban air taxi, reliable cooling begins with an advanced aviation heat exchanger.