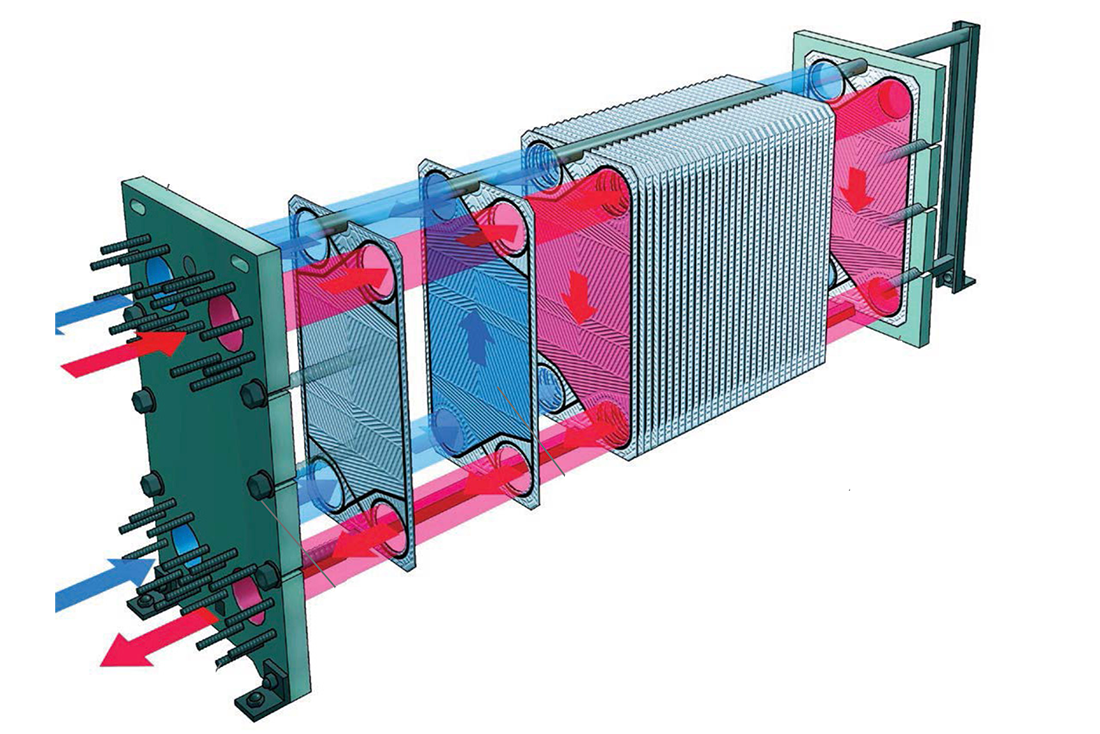

Expandable Plate Heat Exchangers modular heat transfer systems, are widely recognized for their flexibility, efficiency, and space-saving design. Unlike traditional fixed systems, EPHEs allow for the addition or removal of heat transfer plates, making them highly adaptable to changing thermal demands. This unique feature enables easy scaling in response to fluctuating production needs or energy loads without major equipment overhaul. By utilizing corrugated metal plates and gasketed sealing systems, EPHEs provide high heat transfer coefficients while maintaining a compact footprint.

In recent years, advances in material science, digital monitoring, and environmental engineering have expanded the application of EPHEs across industries such as food processing, pharmaceuticals, HVAC, renewable energy, and oil & gas. Their ability to handle corrosive fluids, withstand harsh operating conditions, and integrate into smart industrial systems has positioned EPHEs as a modern solution in both conventional and sustainable process engineering.

What Makes an EPHE “Expandable”?

An Expandable Plate Heat Exchanger is a modular, gasketed plate heat exchanger where you can increase or decrease the number of plates depending on process needs.

Key Advantages:

- Adaptability: As your plant grows or your system demand changes (more flow or heat load), you can simply add more plates.

- Cost-Efficiency: You don’t need to invest in a completely new unit—just expand the current one.

- Ease of Maintenance: Plates can be removed for cleaning, inspection, or replacement without dismantling the entire unit.

Typical Applications:

- HVAC chillers (scaling with building load)

- Food processing lines with seasonal variations

- Industrial setups with future capacity planning in mind

Material Innovations: Not Just Stainless Steel

Traditional plate materials like 316 stainless steel are great for general use. But advanced applications demand more specialized materials:

Exotic Materials:

- Titanium: Excellent for seawater and chloride-containing fluids. Common in desalination plants and marine systems.

- Hastelloy C-276: Withstands aggressive chemicals (e.g., strong acids in pharmaceutical or chemical industries).

- Nickel Alloys: Used where high-temperature corrosion is a concern.

- Graphite Plates: Non-metallic and chemically inert, ideal for ultra-corrosive environments like hydrofluoric acid processing.

This allows EPHEs to be used in places where shell-and-tube or welded exchangers were once the only option.

Smart Monitoring and Digital Twins

The Industry 4.0 movement has reached thermal equipment. Today’s EPHEs can be equipped with smart sensors and cloud-based analytics platforms.

Features Include:

- Temperature & pressure sensors on both sides of the heat exchanger.

- Differential pressure alerts that notify you of fouling or blockages.

- Digital twin software that replicates real-time performance and predicts when cleaning or expansion is needed.

These features reduce energy waste, optimize efficiency, and minimize unplanned shutdowns, particularly in continuous process industries like petrochemicals or breweries.

Self-Cleaning Designs

One of the major issues with plate heat exchangers is fouling—buildup of debris or biological matter that reduces heat transfer.

Modern EPHE Innovations:

- Chevron plate patterns increase turbulence and minimize sedimentation.

- Asymmetrical flow channels that reduce dead zones where particles can settle.

- Some are paired with pulsating flow technology or automatic backflushing systems.

These advancements are vital in industries handling non-filtered water, wastewater, or slurries, where cleaning is frequent and costly.

Use in Renewable Energy Systems

EPHEs are increasingly used in green energy systems due to their high efficiency and compact size.

Renewable Applications:

- Solar thermal heating: Used to transfer solar energy into domestic water or space heating systems.

- Geothermal systems: For heat exchange between ground loops and interior heating/cooling systems.

- Waste heat recovery: Captures low-grade heat from industrial processes to reuse for space heating or preheating water.

Their modularity allows EPHEs to be retrofitted into older plants looking to improve energy efficiency and reduce carbon footprint.

Expandable Plate Heat Exchangers high-efficiency and scalable systems, play a vital role in modern thermal engineering. Their modular design not only supports future expansion and easy maintenance but also aligns with current demands for energy efficiency, sustainability, and intelligent process control. Whether used in renewable energy systems, chemical processing, or industrial cooling, EPHEs offer unmatched adaptability and performance.

As industries continue to shift toward flexible, digital, and environmentally conscious technologies, the role of EPHEs is expected to grow. With ongoing innovations in materials, smart monitoring, and compact designs, EPHEs are not just heat exchangers—they are future-ready thermal solutions built for evolving industrial landscapes.