Introduction

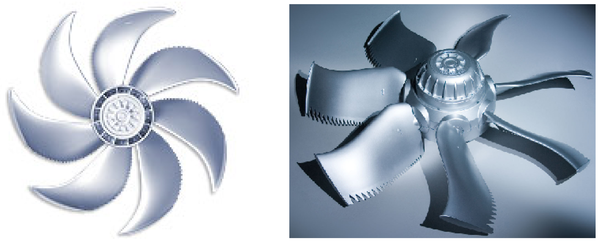

Aerodynamic fan stacks have emerged as a transformative innovation in the realm of air movement and cooling technologies. These precision-engineered components are designed to enhance the efficiency of cooling systems by optimizing airflow, minimizing turbulence, and reducing energy losses. Unlike conventional fan stacks, aerodynamic designs ensure smoother and more consistent air movement, which is critical for maintaining the performance of cooling towers, HVAC systems, and various industrial applications. Additionally, their durable construction from advanced materials like fiberglass-reinforced plastic (FRP) or carbon composites ensures long-lasting performance, even in harsh environmental conditions. In an era where energy efficiency and sustainability are paramount, aerodynamic fan stacks offer a perfect blend of cutting-edge technology and practicality, making them indispensable in industries ranging from power generation to chemical processing.

Key Features and Benefits

1. Enhanced Airflow Efficiency

Aerodynamic fan stacks are engineered to create smooth and laminar airflow by eliminating turbulence and drag. This ensures that the fan operates at peak efficiency, reducing air pressure losses and enabling better cooling performance. The streamlined design minimizes disruptions in airflow, allowing the fan to circulate air more effectively.

2. Energy Savings

By optimizing airflow, these stacks reduce the amount of power required to operate the fans. This efficiency translates into lower energy consumption, leading to significant cost savings over time. In energy-intensive industries like power plants or chemical processing, these savings can have a substantial impact on operational budgets.

3. Noise Reduction

One of the notable benefits of aerodynamic fan stacks is their ability to reduce noise levels. The smooth airflow and reduced turbulence result in quieter operations, making these systems suitable for installations in noise-sensitive environments such as residential areas, hospitals, or urban commercial spaces.

4. Durability and Resistance

Aerodynamic fan stacks are commonly constructed from durable materials such as fiberglass-reinforced plastic (FRP). These materials are resistant to corrosion, extreme weather conditions, and mechanical stress, ensuring a long lifespan even in harsh industrial environments. This durability reduces the need for frequent replacements, lowering maintenance costs.

5. Optimized Design

The shape and size of fan stacks are meticulously designed to meet specific operational needs. A well-optimized stack ensures maximum airflow with minimal energy consumption, providing enhanced performance for both small-scale and large-scale cooling systems. The tailored design also allows for easier integration with existing systems.

6. Improved Thermal Performance

Efficient air handling enhances the thermal performance of cooling systems. By ensuring consistent airflow, aerodynamic fan stacks contribute to better heat dissipation, which is crucial for maintaining the performance of industrial equipment and processes. This is especially important in power plants and chemical processing facilities where thermal management is critical.

Applications

1. Cooling Towers

Aerodynamic fan stacks are essential for cooling towers, improving air distribution and optimizing cooling efficiency. They ensure that the fan can move large volumes of air efficiently, which is critical for maintaining the desired temperature in industrial processes.

2. Power Plants

In power generation facilities, these stacks help in cooling turbines and other components. By improving airflow dynamics, they ensure that the systems operate efficiently, preventing overheating and extending the lifespan of equipment.

3. Chemical and Petrochemical Plants

Chemical processes often generate significant amounts of heat that must be dissipated effectively. Aerodynamic fan stacks facilitate better cooling, ensuring that operations run smoothly without the risk of thermal-related failures.

4. HVAC Systems

In large-scale HVAC systems, aerodynamic fan stacks improve air circulation while reducing energy consumption. This results in more efficient climate control for commercial and industrial buildings.

Future Trends and Innovations

1. Smart Integration

The integration of sensors and IoT (Internet of Things) technology in aerodynamic fan stacks is transforming the way they operate. Smart systems enable real-time monitoring of airflow, temperature, and pressure, allowing operators to make data-driven adjustments for optimal performance. Automation further enhances efficiency by adapting to changing operational conditions.

2. Material Advancements

Researchers are exploring advanced materials such as carbon composites and nanomaterials to improve the strength-to-weight ratio of fan stacks. These innovations not only enhance durability but also make the systems lighter, reducing installation and operational challenges.

3. Eco-Friendly Designs

With the global focus on sustainability, fan stack designs are becoming more eco-friendly. Manufacturers are using recyclable materials and optimizing designs to reduce the carbon footprint of production and operation. Energy-efficient stacks contribute to greener industrial practices.

4. 3D Printing

3D printing technology is revolutionizing the manufacturing of aerodynamic fan stacks. It allows for precise, custom designs that cater to specific operational needs. Additionally, 3D printing can reduce production time and costs, enabling faster deployment of advanced solutions.

5. Aerodynamic Simulations

Advanced computational fluid dynamics (CFD) tools are being used to simulate airflow within fan stacks. These simulations help designers optimize every aspect of the stack’s shape and dimensions, ensuring superior airflow characteristics and reducing inefficiencies.

Maintenance and Best Practices for Aerodynamic fan stacks

1. Regular Cleaning

Dirt and debris can obstruct airflow and reduce efficiency. Regular cleaning of fan stacks ensures unobstructed air movement and maintains the system’s performance.

2. Inspection for Wear and Tear

Periodic inspections for cracks, corrosion, or material degradation are essential to prevent operational failures. Addressing minor issues early can prevent costly downtime and extend the stack’s lifespan.

3. Alignment Checks

Proper alignment between the fan and the stack is crucial to avoid vibrations, noise, and inefficiencies. Misalignment can lead to uneven wear and tear, reducing the overall performance of the system.

4. Material Upgrades

As new materials become available, upgrading outdated fan stacks with advanced aerodynamic designs can significantly enhance performance and efficiency. This is especially important for industries looking to reduce energy costs and improve sustainability.

Conclusion on Aerodynamic fan stacks

Aerodynamic fan stacks represent a pinnacle of innovation in cooling technology, addressing critical challenges like energy inefficiency, noise pollution, and operational durability. By leveraging advanced materials and precise designs, they provide industries with a reliable solution to enhance cooling performance while reducing operational costs and environmental impact. Their ability to minimize energy consumption and maximize airflow efficiency aligns with global sustainability goals, making them a vital component of future-ready cooling systems. As technology continues to evolve, aerodynamic fan stacks are poised to benefit from further advancements in materials science, smart monitoring systems, and manufacturing techniques like 3D printing.