Introduction

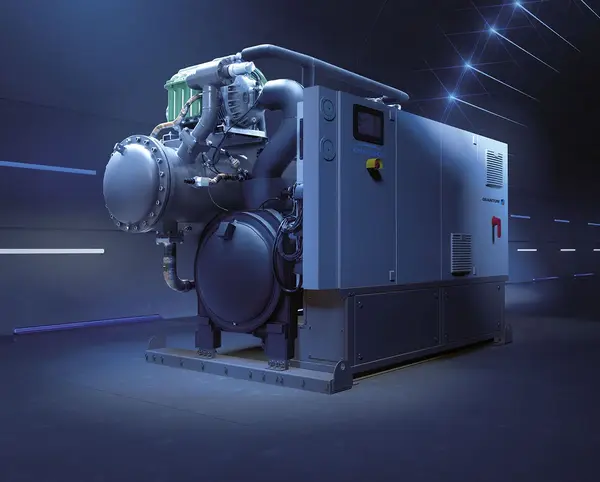

Magnetic Bearing Compressor Chillers. Unlike traditional chillers that rely on mechanical bearings with oil lubrication, magnetic bearing chillers utilize electromagnetic forces to levitate the compressor shaft, completely eliminating friction. This cutting-edge technology results in higher energy efficiency, reduced maintenance costs, and a longer lifespan. Additionally, these chillers operate without oil, which means they are cleaner, quieter, and more sustainable. As businesses and industries move towards green energy solutions and sustainable cooling methods, magnetic bearing compressor chillers are gaining widespread adoption in commercial buildings, data centers, pharmaceuticals, and manufacturing plants. The growing emphasis on energy conservation and carbon footprint reduction has made these chillers an attractive choice for companies looking to optimize cooling performance while minimizing operational costs. With the integration of smart controls, IoT-based remote monitoring, and next-generation refrigerants, the future of magnetic bearing chillers is promising, leading to a new era in HVAC and industrial cooling.

How Magnetic Bearing Compressor Chillers Work

- Magnetic Levitation Technology

- The key feature of these chillers is the use of magnetic bearings to support the rotating shaft.

- Instead of using mechanical contact, strong electromagnetic fields suspend the shaft in the air, allowing it to spin without friction.

- This reduces energy loss, eliminates wear and tear, and enhances overall system longevity.

- Oil-Free Operation

- Traditional centrifugal chillers require oil for lubrication, which can degrade over time and contaminate the refrigerant system.

- Magnetic bearing chillers operate without oil, removing the need for complex oil management systems.

- This results in higher reliability, improved heat transfer efficiency, and easier maintenance.

- Variable Speed Control

- Unlike conventional chillers that operate at fixed speeds, magnetic bearing compressors have variable-speed drive (VSD) technology.

- The system automatically adjusts compressor speed based on cooling demand, leading to significant energy savings during partial load conditions.

- This makes the chiller ideal for buildings and facilities with fluctuating cooling needs.

- Integrated Digital Controls

- These chillers come with advanced microprocessor controls that continuously monitor compressor performance.

- Sensors track temperature, pressure, and load conditions, allowing real-time optimization for maximum efficiency.

- Digital controls also enable predictive maintenance, reducing the risk of sudden breakdowns and increasing system reliability.

Key Advantages of Magnetic Bearing Compressor Chillers

Energy Efficiency

- Since magnetic bearing chillers have no mechanical friction, they consume less energy than traditional chillers.

- Studies show that these systems can achieve 30% to 50% energy savings, especially in part-load conditions.

- The variable speed drive (VSD) further optimizes energy consumption, making them an excellent choice for facilities with dynamic cooling demands.

Reduced Maintenance Costs

- Traditional chillers require frequent maintenance due to mechanical wear, lubrication system upkeep, and potential oil leaks.

- With no oil and no mechanical bearings, these chillers experience less wear and tear, resulting in lower maintenance costs and longer operational life.

- They also eliminate the need for oil changes, oil pumps, and oil filters, simplifying system maintenance.

Quiet Operation

- Mechanical compressors produce noise due to bearing friction and vibrations.

- Magnetic bearing technology eliminates metal-to-metal contact, significantly reducing noise levels.

- These chillers typically operate at sound levels below 75 dB, making them ideal for hospitals, office buildings, and data centers where noise reduction is crucial.

Environmentally Friendly

- The absence of oil in the system prevents oil contamination of refrigerants, improving heat exchanger performance and system longevity.

- Many magnetic bearing chillers are designed to work with low-GWP (Global Warming Potential) refrigerants, contributing to green building certifications like LEED.

- Their high energy efficiency reduces carbon emissions, making them a sustainable choice for cooling applications.

Compact and Lightweight

- Magnetic bearing compressors are smaller and lighter than traditional centrifugal compressors.

- This reduces installation space requirements, making them a great choice for retrofit projects and buildings with space constraints.

- The lightweight design also lowers shipping and handling costs during installation.

Applications of Magnetic Bearing Compressor Chillers

- Commercial Buildings

- Used in office complexes, shopping malls, hospitals, and hotels for energy-efficient cooling.

- Reduces operating costs while maintaining precise temperature control.

- Data Centers

- Magnetic bearing chillers are perfect for data centers, where cooling must be reliable and energy-efficient.

- Their low noise and oil-free design prevent contamination issues in sensitive electronic environments.

- Pharmaceutical Industry

- Essential for cleanroom environments where oil contamination could disrupt pharmaceutical production.

- Provides high-precision cooling for temperature-sensitive drugs and medical storage.

- HVAC Systems

- Used in large-scale air conditioning systems for buildings and industrial facilities.

- Helps reduce energy consumption in HVAC applications while maintaining stable indoor climates.

- Manufacturing Plants

- Provides efficient process cooling for industries such as automotive, food processing, and electronics.

- Minimizes operational downtime and improves equipment performance.

Future Innovations in Magnetic Bearing Chillers

- Integration with Smart Building Systems

- AI-driven smart controls will enable real-time energy management, optimizing cooling loads dynamically.

- Smart algorithms will allow chillers to predict future cooling needs and adjust performance accordingly.

- Use of Next-Gen Refrigerants

- As regulations phase out high-GWP refrigerants, magnetic bearing chillers will adopt low-GWP and natural refrigerants like R-1234ze and CO₂.

- This transition will further improve environmental sustainability.

- Enhanced IoT and Remote Monitoring

- IoT-enabled chillers will provide remote diagnostics and predictive maintenance.

- Facility managers will be able to track performance metrics in real time and receive automatic alerts for maintenance.

- Hybrid Cooling Solutions

- Newer models will integrate magnetic bearing technology with hybrid cooling systems, such as absorption cooling, to further enhance energy efficiency.

- This will help industries achieve carbon neutrality while maintaining reliable cooling performance.

Conclusion

Magnetic Bearing Compressor Chillers represents a major technological advancement in the cooling industry, offering numerous benefits over conventional chillers. By eliminating mechanical friction and the need for oil lubrication, these chillers provide exceptional energy efficiency, lower maintenance requirements, and enhanced reliability. Their quiet operation and compact design make them an ideal choice for commercial, industrial, and data center applications where efficiency and performance are crucial. As industries continue to adopt sustainable and energy-efficient cooling solutions, magnetic bearing chillers will play a pivotal role in shaping the future of HVAC and refrigeration systems. The integration of artificial intelligence, IoT-based predictive maintenance, and eco-friendly refrigerants will further enhance their capabilities, ensuring they remain at the forefront of the cooling industry. With increasing global awareness of energy conservation and carbon emissions, the demand for advanced cooling technologies like magnetic bearing compressor chillers will only continue to rise. Investing in this next-generation cooling solution is not just a step towards operational efficiency, but also a commitment to a greener and more sustainable future.