Metamaterial heat exchanger technology represents a radical evolution in thermal management, where engineered materials are designed to control heat in ways conventional materials simply cannot. Unlike traditional systems that depend on metal alloys or composite materials for heat transfer, metamaterial heat exchangers use scientifically designed microstructures to direct, enhance, or even inhibit thermal energy flow with precision.

These metamaterials are not naturally occurring. They are man-made, with unique internal structures that enable properties such as anisotropic heat conduction, thermal cloaking, and heat focusing—enabling thermal functionalities that were once considered impossible. As global industries strive for higher energy efficiency, miniaturization, and smart heat control, metamaterial heat exchangers emerge as a powerful solution to tackle modern challenges in aerospace, microelectronics, energy, and beyond.

What Are Metamaterials?

Metamaterials are artificially engineered substances designed to exhibit properties not commonly found in nature. Their behavior is governed not by their chemical composition but by their structural geometry. These microscopic structures can interact with various forms of energy—including electromagnetic waves, sound, and heat.

Key Properties of Thermal Metamaterials:

- Negative thermal conductivity: Heat flows from cold to hot under specific engineered conditions.

- Thermal cloaking: Makes regions thermally “invisible” by directing heat around them.

- Anisotropy: Heat is conducted more in one direction than another.

- High thermal emissivity control: Ability to manipulate radiative heat transfer precisely.

- Thermal diode behavior: Allowing heat to flow in only one direction.

These capabilities allow for entirely new forms of thermal control that are impossible with copper, aluminum, or even advanced ceramics.

How Does a Metamaterial Heat Exchanger Work?

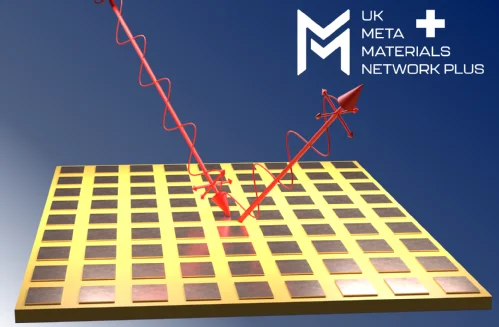

Instead of relying solely on mass and surface area to transfer heat, metamaterial heat exchangers are designed using microstructured geometries that can manipulate the flow of heat at a sub-wavelength level.

Functional Mechanisms:

- Microstructure-Driven Transfer

Arrays of microscopic structures redirect heat to maximize or minimize transfer based on need—like a thermal lens focusing heat. - Selective Insulation

Certain sections of the exchanger are designed to resist heat transfer, acting like internal insulators. - Directional Heat Flow

Anisotropic properties ensure heat moves only in a desired direction, improving transfer efficiency while minimizing waste. - Dynamic Control

Some designs incorporate smart metamaterials that change behavior with temperature or magnetic fields, enabling adaptive performance.

Design and Fabrication Techniques

The manufacturing of metamaterial heat exchangers relies on advanced fabrication technologies, including:

- 3D Nano-Printing: Used to precisely shape microscopic heat-guiding structures.

- Electron Beam Lithography: For extreme precision at the nanoscale.

- Laser Interference Lithography: Suitable for creating periodic thermal patterns.

- Additive Manufacturing (AM): For scalable production of complex structures with tailored thermal properties.

These processes allow engineers to fine-tune the thermal behavior of the exchanger for specific applications.

Recent Innovations and Research

- Programmable Metamaterials

Materials that can change heat transfer characteristics in real-time using electrical or magnetic inputs. - Topological Metamaterials

Use exotic geometry to trap or guide heat in specific paths—like sound waves in a musical instrument. - Hybrid Structures with Phase Change Materials (PCM)

Combine metamaterials with PCMs for dynamic heat storage and release, perfect for energy-efficient buildings. - Metamaterial Radiators

Tailored surfaces for selective thermal radiation, especially in space or extreme temperature environments. - Thermal Logic Circuits

Devices that compute using heat instead of electricity, enabled by metamaterial control of thermal pathways.

Metamaterial heat exchanger technology is not just a refinement—it’s a paradigm shift in how we transfer, manage, and even think about heat. With the power to guide thermal energy through complex paths, protect sensitive zones, and enhance heat transfer in compact footprints, metamaterials open the door to the next generation of energy systems, electronics, and advanced manufacturing.

While widespread adoption still faces hurdles like cost and complexity, the potential benefits in efficiency, precision, and adaptability are simply too significant to ignore. As research advances and 3D nanofabrication becomes more affordable, metamaterial heat exchangers will soon move from the lab to the factory floor, powering tomorrow’s green, intelligent, and compact thermal systems.