Introduction

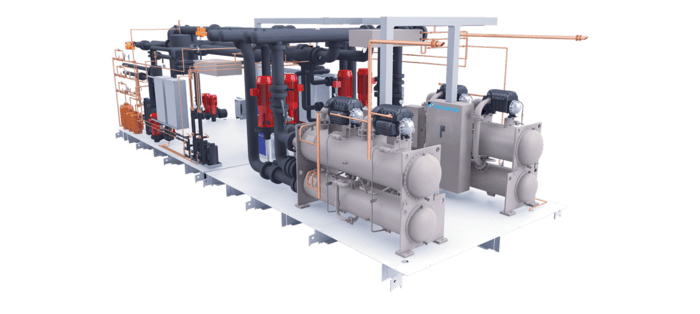

Modular cooling plants represent a revolutionary advancement in industrial and commercial cooling technology. Unlike traditional centralized cooling systems, modular cooling plants are composed of pre-engineered, factory-assembled modules that can be easily scaled, customized, and deployed to meet dynamic cooling demands. These systems provide high energy efficiency, reduced installation time, and enhanced flexibility, making them ideal for industries such as data centers, pharmaceuticals, manufacturing, district cooling, and HVAC applications. As industries increasingly prioritize sustainability, operational efficiency, and cost-effectiveness, modular cooling plants are emerging as the preferred solution due to their adaptability and innovative design. Their ability to integrate with renewable energy sources, utilize intelligent automation, and incorporate advanced heat exchange technologies sets them apart from conventional cooling systems. With continuous innovations in materials, smart controls, and energy optimization, modular cooling plants are shaping the future of industrial cooling solutions.

Key Features & Elaborations

Scalability

- Modular Expansion: The cooling plant consists of individual modules that can be added or removed based on cooling requirements. This allows businesses to scale their cooling capacity without major infrastructure changes.

- Adaptability to Demand: Instead of investing in a large, fixed-capacity system, users can start with a smaller setup and expand as the cooling needs grow.

- Cost-Effective Growth: Since additional cooling capacity can be added as needed, businesses avoid over-investing in unused capacity.

Pre-Assembled Design

- Factory-Built & Tested: Modular cooling plants are manufactured and tested in a controlled environment before being shipped to the installation site, ensuring reliability and minimizing on-site issues.

- Quick Installation: Unlike traditional cooling systems that require significant on-site assembly, modular plants arrive ready for deployment, reducing downtime and installation costs.

- Plug-and-Play Setup: Many modular systems are designed for easy integration with existing cooling infrastructure, simplifying the installation process.

Energy Efficiency

- Optimized Cooling Performance: Modular cooling plants use advanced control systems to adjust cooling capacity based on real-time demand, minimizing energy waste.

- Efficient Components: Many modular plants incorporate energy-saving technologies such as variable speed drives (VSDs), high-efficiency compressors, and advanced heat exchangers.

- Load Sharing: Multiple cooling modules distribute the cooling load efficiently, reducing strain on individual components and improving overall energy efficiency.

Compact Footprint

- Space-Saving Design: Modular cooling plants are designed to occupy minimal floor space, making them ideal for locations with space constraints.

- Stackable & Configurable: Some systems allow vertical stacking or side-by-side arrangements, optimizing space utilization.

- No Need for Large Mechanical Rooms: Since many components are built into the modular system, users often require less dedicated space for cooling infrastructure.

Application Versatility

- Data Centers: Ensures optimal cooling for IT infrastructure, preventing overheating and improving energy efficiency.

- Industrial Processes: Used in manufacturing plants to maintain process temperatures and enhance equipment performance.

- HVAC Systems: Supports commercial and residential buildings by providing reliable air conditioning.

- District Cooling: Ideal for centralized cooling solutions in urban areas, serving multiple buildings from a single cooling plant.

- Healthcare & Pharmaceuticals: Maintains strict temperature control for sensitive medical equipment and pharmaceutical production.

Unique Future Trends & Innovations in Modular Cooling Plants

- AI-Powered Self-Healing Cooling Systems

- Advanced AI detects micro-failures in cooling modules and automatically reroutes load to prevent system downtime.

- Uses real-time machine learning models to predict wear and trigger preventive maintenance before failures occur.

- Liquid Metal Cooling Technology

- Experimental cooling solutions using non-toxic liquid metals (like gallium-based alloys) for ultra-fast heat transfer.

- Potentially revolutionizes cooling efficiency in high-performance computing and industrial applications.

- Bio-Inspired Cooling Designs

- Heat exchangers and cooling surfaces are being redesigned using structures inspired by nature (e.g., termite mounds, shark skin) for enhanced thermal efficiency.

- Biomimetic airflow patterns help improve cooling capacity while reducing energy consumption.

- Graphene-Based Heat Dissipation

- Integration of graphene coatings in heat exchangers enhances thermal conductivity, reducing the need for high-power cooling systems.

- Enables ultra-thin, lightweight cooling modules for compact applications.

- Fog-Assisted Cooling Modules

- Utilizing micro-mist and fog-based cooling to enhance air-cooled heat exchanger efficiency, reducing reliance on traditional water-based systems.

- Provides high cooling efficiency in dry and arid climates without excessive water usage.

- Swarm Cooling Networks

- Decentralized modular cooling plants work as an intelligent “swarm,” adjusting load distribution dynamically across multiple cooling points.

- Ideal for smart cities and IoT-based industrial zones with fluctuating cooling demands.

- Hyperloop Cooling Systems for Industrial Applications

- Concepts involving vacuum-based, high-velocity air cooling inspired by Hyperloop transport systems.

- Could lead to ultra-fast heat removal with minimal energy input.

- Modular Cooling “As a Service” (CaaS)

- Subscription-based cooling solutions where businesses pay only for the cooling capacity they use.

- Reduces upfront investment while ensuring access to cutting-edge cooling technology.

- Quantum Computing-Assisted Cooling Optimization

- Use of quantum algorithms to simulate and optimize heat transfer in real-time, unlocking ultra-efficient cooling solutions.

- Could redefine thermal management strategies in complex industrial setups.

Conclusion

Modular cooling plants provide a future-proof alternative to traditional cooling methods, offering unparalleled efficiency, reliability, and sustainability. As industries move toward smart and eco-friendly infrastructure, modular cooling technology will play a critical role in shaping modern cooling strategies, ensuring optimal performance while minimizing environmental impact. Investing in these innovative cooling solutions is not just a trend but a necessity for industries looking to achieve long-term efficiency and sustainability. The future of cooling technology lies in the adaptability, efficiency, and sustainability offered by modular cooling plants. With advancements such as AI-driven cooling optimization, smart IoT-based monitoring, and innovative heat recovery systems, these plants are revolutionizing industrial and commercial cooling. As environmental regulations tighten and energy costs continue to rise, businesses must invest in flexible and energy-efficient cooling solutions that can scale with their needs.