Introduction

Thermal balancing technology is a fundamental aspect of heat management that ensures uniform temperature distribution, minimizes energy loss, and prevents overheating or overcooling in various applications. Whether in industrial machinery, HVAC systems, power plants, automotive cooling, or electronics, maintaining thermal balance is crucial for optimizing efficiency, improving longevity, and reducing operational costs. With advancements in intelligent sensors, AI-driven automation, and innovative heat transfer methods, thermal balancing technology has evolved to meet modern energy conservation demands. Industries now rely on sophisticated cooling mechanisms, smart materials, and adaptive controls to enhance performance while reducing environmental impact.

Key Aspects of Thermal Balancing Technology

Enhanced Heat Transfer Mechanisms

Effective thermal balancing relies on advanced heat transfer mechanisms that maximize efficiency and minimize thermal losses.

- Counterflow Heat Exchangers – These provide superior heat transfer by ensuring that hot and cold fluids flow in opposite directions, optimizing temperature gradients.

- Phase-Change Materials (PCMs) – Used in cooling and heating applications, PCMs absorb and release heat efficiently during phase transitions, helping in temperature stabilization.

- Thermal Conductivity Enhancement – The use of nanofluids and advanced thermal coatings enhances heat transfer rates in industrial processes and electronics cooling.

- Active Cooling & Heating Systems – Systems like thermoelectric coolers and heat pumps dynamically adjust temperature based on operational requirements.

Advanced Fluid Dynamics and Flow Control

Proper flow regulation ensures that thermal balancing is maintained across all components of a system.

- Optimized Fluid Flow in Heat Exchangers – Uneven fluid distribution can create hotspots and inefficiencies. Computational fluid dynamics (CFD) simulations help design better flow patterns.

- Hydraulic Balancing in HVAC – Proper water and refrigerant distribution in HVAC systems prevents temperature imbalances across different zones.

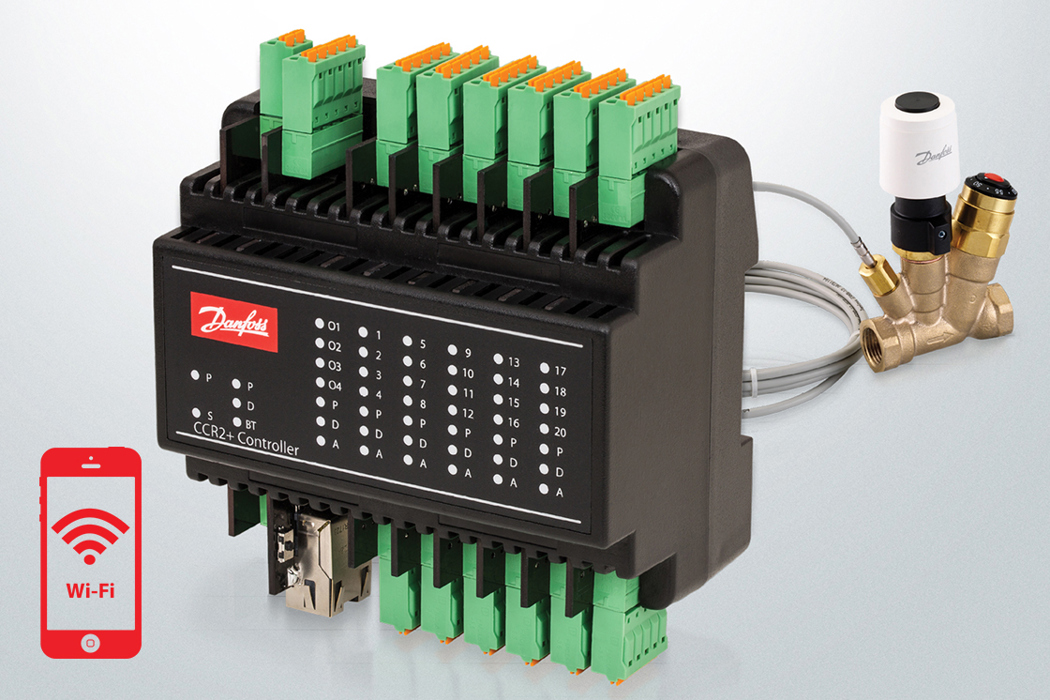

- Pumps and Valves in Industrial Cooling – Smart pumps and control valves regulate coolant flow in process industries, ensuring precise temperature control.

Smart Thermal Management Systems

Integration of intelligent controls and automation enhances real-time thermal regulation.

- AI-Based Climate Control – Smart buildings use AI and IoT sensors to adjust temperature settings based on occupancy, weather, and energy demand.

- Adaptive Engine Cooling – In automotive applications, electronic thermostats and active grille shutters adjust cooling based on driving conditions.

- Data Center Cooling Optimization – AI-driven air and liquid cooling systems prevent overheating in high-performance computing environments.

Prevention of Hotspots and Cold Spots

Uneven temperature distribution can cause serious issues in industrial processes and equipment performance.

- Electronics and Semiconductor Manufacturing – Precision cooling ensures that components do not overheat, leading to longer device lifespans.

- Metallurgy and Welding Processes – Controlled heating and cooling prevent thermal cracking and warping of metal structures.

- Food Processing & Storage – Maintaining uniform temperature prevents spoilage and ensures product consistency.

Thermal Expansion and Stress Mitigation

Thermal stress is a major concern in high-temperature environments, and balancing techniques help mitigate damage.

- Expansion Joints in Pipelines – Prevents cracking due to temperature fluctuations in industrial pipelines.

- Thermal Shock Resistance in Glass & Ceramics – Advanced coatings and composite materials help withstand sudden temperature changes.

- Structural Integrity in Aerospace Engineering – Aircraft engines and fuselages use heat-resistant alloys and insulation to manage extreme thermal stress.

Energy Efficiency and Sustainability

Thermal balancing plays a critical role in energy conservation and sustainability efforts.

- Waste Heat Recovery – Industries harness excess heat through heat exchangers and cogeneration systems to improve overall energy efficiency.

- Solar Thermal Energy Storage – Advanced storage systems enable efficient heat utilization in solar power plants.

- High-Performance Insulation Materials – Reducing thermal losses in buildings, industrial equipment, and transportation improves energy conservation.

Increased Equipment Longevity and Reliability

Maintaining optimal thermal conditions ensures the durability of mechanical and electrical components.

- Automotive Battery Thermal Management – Prevents overheating and degradation in electric vehicle (EV) batteries.

- Industrial Gearboxes & Bearings – Proper lubrication and cooling prevent excessive wear and tear in machinery.

- Aerospace Thermal Protection – Heat shields and advanced insulation materials extend the lifespan of spacecraft and aircraft components.

Adaptive Thermal Protection for Extreme Environments

Certain industries operate in extreme temperature conditions where advanced thermal balancing is crucial.

- Cryogenic Cooling Systems – Used in medical, space, and scientific applications to maintain ultra-low temperatures.

- High-Temperature Furnaces – Controlled heat distribution ensures consistent processing in metallurgy and ceramics.

- Geothermal Power Plants – Regulates underground heat extraction to maximize efficiency and sustainability.

Applications Across Various Industries

- HVAC Systems – Enhances indoor climate control and energy efficiency.

- Industrial Cooling & Refrigeration – Prevents overheating in chemical, pharmaceutical, and food processing industries.

- Automotive & Aerospace – Regulates engine and battery temperatures for improved performance.

- Data Centers & Electronics – Prevents overheating of servers and microprocessors.

- Renewable Energy Systems – Optimizes heat utilization in solar and geothermal power generation.

Conclusion

Thermal balancing technology is a critical aspect of modern heat management, ensuring stable and efficient temperature regulation across various industries. From HVAC systems and industrial cooling to automotive engineering and renewable energy solutions, thermal balancing enhances operational efficiency, prevents equipment failure, and reduces energy consumption. By implementing advanced heat transfer techniques, AI-driven automation, and intelligent thermal controls, industries can optimize performance while minimizing maintenance costs and environmental impact. As technological advancements continue, thermal balancing strategies are becoming more sophisticated, integrating real-time monitoring, adaptive cooling systems, and sustainable energy solutions. The growing emphasis on energy conservation and climate-friendly practices further drives the need for efficient thermal management in industrial, commercial, and residential applications. In the future, innovations such as smart materials, nanotechnology-based cooling fluids, and AI-powered predictive maintenance will further revolutionize thermal balancing technology.