Introduction

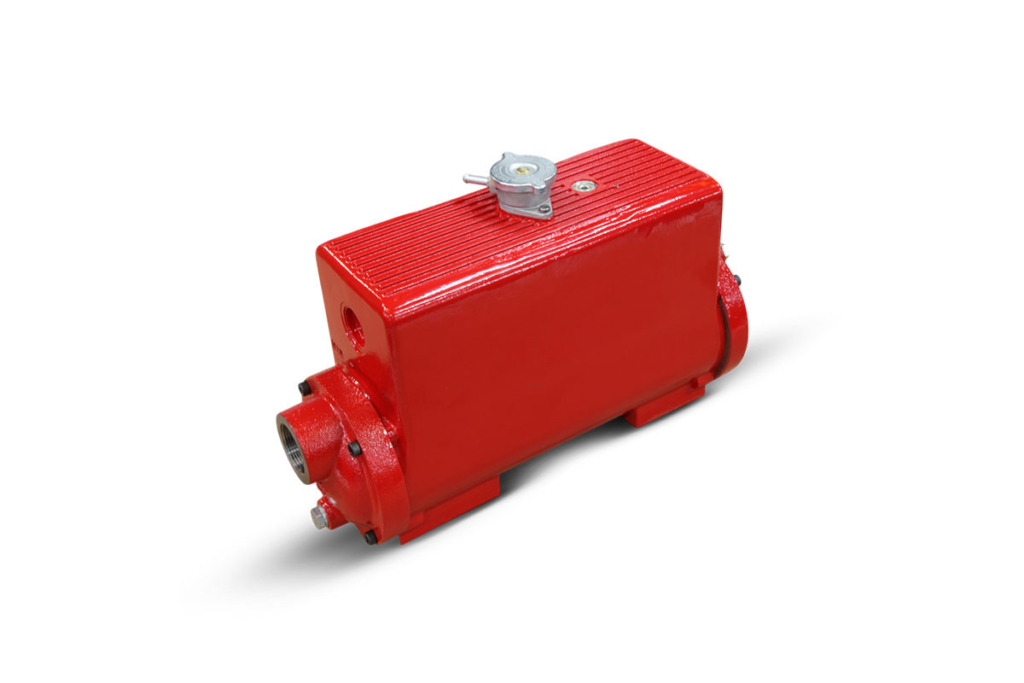

Header tank heat exchanger system combines a heat exchanger with a header tank—a small auxiliary tank mounted at a high point in a closed-loop fluid system. While the heat exchanger is responsible for transferring heat from one fluid to another, the header tank plays a crucial supporting role in maintaining the system’s pressure, fluid level, and operational reliability. It’s commonly used in engine cooling systems, HVAC circuits, and industrial thermal systems where stable operation is essential.

Role of the Header Tank

The header tank serves several vital purposes:

- Pressure Stabilization: As fluids heat up, they expand. This increase in volume can raise the pressure in a closed system. The header tank absorbs this expanded volume, helping maintain stable pressure and preventing damage to system components.

- Fluid Reservoir: During normal operation, some amount of fluid may be lost due to evaporation or minor leaks. The header tank acts as a reservoir to make up for this loss and ensures that the system remains full at all times.

- Thermal Expansion Management: With temperature changes, the volume of the fluid increases or decreases. The header tank adjusts for this expansion and contraction without creating air pockets or low-pressure areas.

- Air Separation: Trapped air in a heat exchanger system can significantly reduce heat transfer efficiency. Since the header tank is placed at the highest point in the system, air bubbles naturally rise into it. These can be removed manually or via an automatic air bleed valve.

- Easy Maintenance: The tank provides a convenient location to fill or top-up the fluid without disturbing the main system. It may also have features like sight glasses or level sensors to monitor fluid levels.

How the System Works

In operation, a pump circulates a working fluid—often water, glycol, or thermal oil—through the heat exchanger and the entire loop. As the fluid absorbs heat (from an engine, industrial machine, or HVAC system), it expands. This extra volume flows into the header tank. When the fluid cools down and contracts, it’s drawn back into the loop, keeping the system full at all times.

Because the header tank is located above the highest point of the loop, it acts as a natural collection point for air. Air bubbles in the system rise into the tank, where they can be vented out, preventing problems like pump cavitation, reduced heat transfer, or corrosion.

Applications

Header tank-equipped heat exchangers are used in a wide range of applications:

- Automotive systems: Car engines and generators use them to ensure the cooling system can handle expansion and avoid overheating.

- Marine engines: Ships experience fluctuating loads and temperatures; header tanks help stabilize the cooling system.

- HVAC and building chillers: In large buildings, they help manage the fluid loop in chilled water and hydronic heating systems.

- Industrial process cooling: Machines and production lines often rely on closed-loop systems where fluid loss or overheating would be costly.

- Medical and lab equipment: Devices like MRI scanners or laser systems need precise, uninterrupted cooling.

Design Considerations

When designing or installing a system with a header tank, several factors are important:

- Elevation: The tank must be mounted at the highest point of the system to allow air to rise into it naturally.

- Volume: The tank needs to have enough capacity to handle the system’s thermal expansion without overflowing.

- Material: The tank must be made of materials that can handle the fluid type and temperature range—often stainless steel, aluminum, or high-grade plastic.

- Connections: The piping to and from the tank should be properly sized and located to allow gravity return and air venting.

- Monitoring: Including sensors and visual indicators helps operators track fluid levels and system status.

Conclusion

Header tank heat exchanger system is an essential configuration for any closed-loop thermal management setup where stability, efficiency, and reliability are critical. While the heat exchanger handles the actual transfer of heat, the header tank plays a silent but crucial role in managing pressure fluctuations, removing air, accommodating thermal expansion, and ensuring the system remains properly filled at all times.

By integrating a header tank, you significantly enhance the performance and durability of the entire system—whether it’s used in automotive cooling, industrial processes, HVAC applications, or marine environments. Properly designed and maintained, this combination offers seamless thermal regulation, minimal maintenance interruptions, and long-term operational assurance.