Introduction

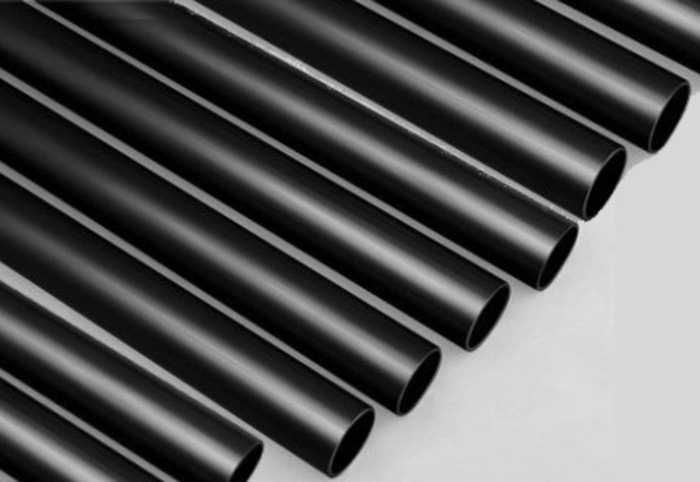

Carbon steel tubes are among the most widely used piping and tubing materials in various industrial and structural applications. Known for their strength, durability, and cost-efficiency, these tubes are made primarily from iron and carbon, with minimal alloying elements. Depending on the carbon content and manufacturing process, carbon steel tubes can be tailored for a wide range of uses—from high-pressure boilers and heat exchangers to oil pipelines and structural supports. Their excellent mechanical properties, weldability, and thermal performance make them a reliable solution in demanding environments across sectors such as power generation, construction, oil & gas, and manufacturing.

Manufacturing Types of Carbon Steel Tubes:

Seamless Carbon Steel Tubes:

- Manufactured through extrusion or rotary piercing, without any welding seam.

- Key Advantages:

- High-pressure and high-temperature resistance

- Uniform strength throughout the tube

- Common in boilers, heat exchangers, and oil/gas applications

Welded Carbon Steel Tubes:

- Made by rolling a steel strip and welding the seam longitudinally.

- Key Advantages:

- Lower cost compared to seamless

- Easier to manufacture in larger sizes

- Suitable for medium-pressure applications like HVAC or fluid transfer

Features of Carbon Steel Tubes:

- Excellent Mechanical Strength: Can withstand high stress and pressure without deforming.

- Moderate Corrosion Resistance: Performs well in non-corrosive to mildly corrosive environments; can be enhanced with coatings or linings.

- Good Thermal Conductivity: Adequate for use in heat exchangers and thermal transfer systems.

- High Weldability and Machinability: Easily cut, drilled, bent, and welded to fit specific design needs.

- Availability: Easily available in various thicknesses, diameters, and lengths.

- Versatility: Can be used in a wide range of industries.

Limitations and Considerations:

Despite its many advantages, carbon steel tubes have some limitations:

- Susceptible to Corrosion: Especially in marine or chemical environments if not properly protected.

- Weight: Heavier than aluminum or composite materials.

- Brittleness (in high carbon content): High carbon steel can be brittle and less impact-resistant.

- Maintenance: May require protective coatings or regular inspections in corrosive environments.

Common Standards and Grades:

Depending on application and geography, carbon steel tube are manufactured under various international standards, such as:

- ASTM A179 / A192 / A210 / A53 / A106

- DIN 17175

- EN 10216

- IS 1239 / IS 3589 (Indian Standards)

- API 5L / API 5CT (For oil & gas industry)

Each standard covers aspects like chemical composition, mechanical properties, dimensions, and testing protocols.

Surface Finishes & Protection Options:

To improve corrosion resistance and aesthetics, carbon steel tube may come with:

- Galvanized (zinc-coated) finish

- Black oxide coating

- Oil coating or varnish

- Painted or epoxy-coated

- Bare finish (for internal use or further treatment)

Conclusion

Carbon steel tubes offer a robust, versatile, and economical option for industries requiring high performance under pressure, heat, or structural loads. With seamless and welded variants available, and compatibility with various coatings and standards, they can be customized to meet specific engineering and operational needs. While they may require protection in corrosive environments, their overall value, availability, and adaptability make them an essential material in modern industrial systems. Whether for transporting fluids, transferring heat, or supporting mechanical structures, carbon steel tubes deliver dependable performance you can count on.