Introduction

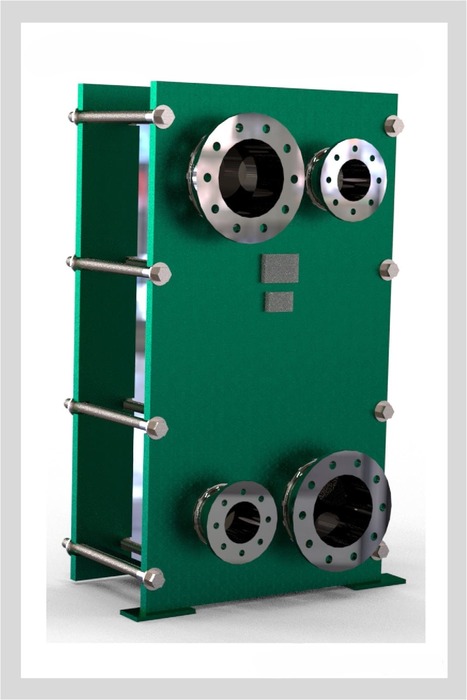

Plate Type Condenser Exchangers is a type of compact heat exchanger that uses stacked metal plates to condense a vapor (like refrigerant, steam, or process gas) into a liquid. This condensation occurs by transferring the vapor’s heat to a cooling fluid (commonly water or glycol solution) that flows through alternating channels within the plate stack.

It is designed for high thermal efficiency, space-saving installations, and low refrigerant charge environments — making it ideal for HVAC, industrial processing, and refrigeration applications.

Plate Type Condenser Exchanger – How It Works

Basic Operation:

- The condenser consists of a series of metal plates stacked together, with gaskets (or brazed seams) forming flow channels between them.

- Hot vapor enters one set of alternating channels.

- Cooling fluid enters the adjacent channels in a counterflow direction to maximize thermal gradient.

- The heat from the vapor passes through the metal plates into the cooling fluid.

- As a result, the vapor loses latent heat and condenses into a liquid.

- The condensate and heated coolant exit separately from their respective outlets.

Flow Configuration:

- Countercurrent flow is most common (cooling fluid and vapor flow in opposite directions), providing maximum temperature difference.

- Parallel or crossflow may be used in specific layouts.

Construction & Components

Plates

- Thin, corrugated metal sheets (typically 0.3–0.7 mm thick).

- Corrugation promotes turbulence, improving heat transfer.

- Materials: Stainless Steel (304/316), Titanium, Hastelloy, Nickel alloys.

Gaskets

- Seal the flow channels and direct fluids to alternate channels.

- Materials: EPDM, NBR, Viton (selected based on fluid compatibility and temperature).

Frame (For Gasketed Units)

- Composed of:

- Fixed Head (Stationary End Plate)

- Movable Head (Pressure Plate)

- Carrying and guiding bars (hold plates in position)

- Compression bolts

- Designed to be opened for plate cleaning or replacement.

Brazing or Welding (For Compact Units)

- Brazed Plate Heat Exchangers: Plates are permanently joined using copper or nickel alloy brazing — compact, sealed, and maintenance-free.

- Welded Plate Heat Exchangers: Plates are welded together for handling aggressive or high-pressure fluids. No gaskets involved.

Selection Considerations on Plate Type Condenser Exchanger

- Type of vapor and coolant (chemical compatibility).

- Condensation rate required (based on duty).

- Installation space available.

- Cleaning frequency (select gasketed if frequent).

- Pressure and temperature range.

- Budget and lifecycle cost.

- Corrosion risk (choose suitable plate material).

Conclusion

Plate type condenser heat exchangers offer an efficient, compact, and flexible solution for condensing vapors such as refrigerants or steam into liquid form by transferring their heat to a cooling fluid. Their modular plate design, high heat transfer efficiency, and space-saving structure make them an excellent choice across industries such as HVAC, chemical processing, food and beverage, power generation, and marine systems.

Whether in gasketed, brazed, or welded form, these heat exchangers support a wide range of operating conditions, with low refrigerant charge, easy maintenance, and fast thermal response. However, they are best suited for clean fluids and systems where moderate pressure and temperature ranges are sufficient.